From hours to seconds: the ecological adhesive revolution offers an alternative to synthetics

How can a dextrin-based ecological alternative replace traditional petroleum-based synthetic adhesives and contribute to industrial sustainability? A research project at the Faculty of Chemistry, Brno University of Technology (FCH VUT), in collaboration with the company TOPCORE service, offers the answer — newly developed natural adhesives respond to the growing demand for eco-friendly solutions and help reduce reliance on petroleum resources. We spoke with experts from the Materials Research Centre at FCH VUT — Tomáš Solný, Jan Hajzler, and Michal Marko — about the technological advantages and broad industrial potential of these adhesives.

Starch Instead of Oil

The project Development of New Eco-Friendly Adhesives Based on Dextrin brings both ecological and economic benefits. Dextrin is a natural polysaccharide derived from starch, easy to process and cost-effective. The newly developed adhesives are not only more environmentally friendly but also technically competitive — they meet strength and elasticity requirements. Additionally, they allow for a so-called dry-mix solution, meaning they can be transported in dry form and mixed on-site, reducing costs and wastewater generation.

The project is led by the company TOPCORE service in collaboration with Brno University of Technology (VUT), which acts as the scientific partner. “I’ve been working on ecological adhesives for over ten years, starting during my PhD studies. I was also the responsible person at VUT for one of the major TRIO projects, FV40379, conducted with the same company, which aimed to develop dry dextrin-based adhesives. This new project is essentially a continuation. In the meantime, I’ve also worked on several innovation vouchers focused on similar topics,” explains Tomáš Solný, the project’s principal investigator.

Collaboration with the company is very close. In addition to researchers from FCH VUT, other key people include Lucie Trojtlerová, head of the TOPCORE service lab, and company owners Zdeněk Vařejka, Petr Červinka, and Petr Vařejka. “We regularly meet at work meetings and have also made many site visits to customers. This provides us with feedback directly from the field. It’s mostly positive, although there are always areas that need fine-tuning. That’s the tricky part about our adhesives,” says Tomáš Solný with a smile.

Reducing production costs plays a crucial role in industry. Although it's not the main goal, this project also focuses on it. The primary aim is to replace petroleum-based adhesives with a natural alternative, reducing carbon dioxide emissions. These adhesives also support corporate ESG reporting goals, which are becoming increasingly important across sectors. The project also utilizes by-products from other industries, especially energy, which serve as additives or micro-fillers.

Dextrin as a Key Raw Material

Developing new adhesives requires detailed material research. The composition of fillers (e.g., limestone, kaolins, micro-fillers) and their compatibility with the system is examined. The key raw material is dextrin, derived from modified starches such as potato, corn, or beans. Different types of dextrins vary in structure and properties, so the selection depends on the specific application. For instance, potato dextrin is better for liquid adhesives, while bean dextrin provides higher viscosity. “We tested a bean-dextrin sample in Poland on protective edges, which are also part of the project. These were so-called U-edges — used to protect items like monitors on all sides,” explains Tomáš Solný. “We arrived with my colleague, applied the adhesive to the machine — it was a bit thick, but manageable. Then, right in the middle of the test, the power went out. We’d spent four months arranging that test, and the power hadn’t gone out there in two years. And just when we show up — boom,” he laughs.

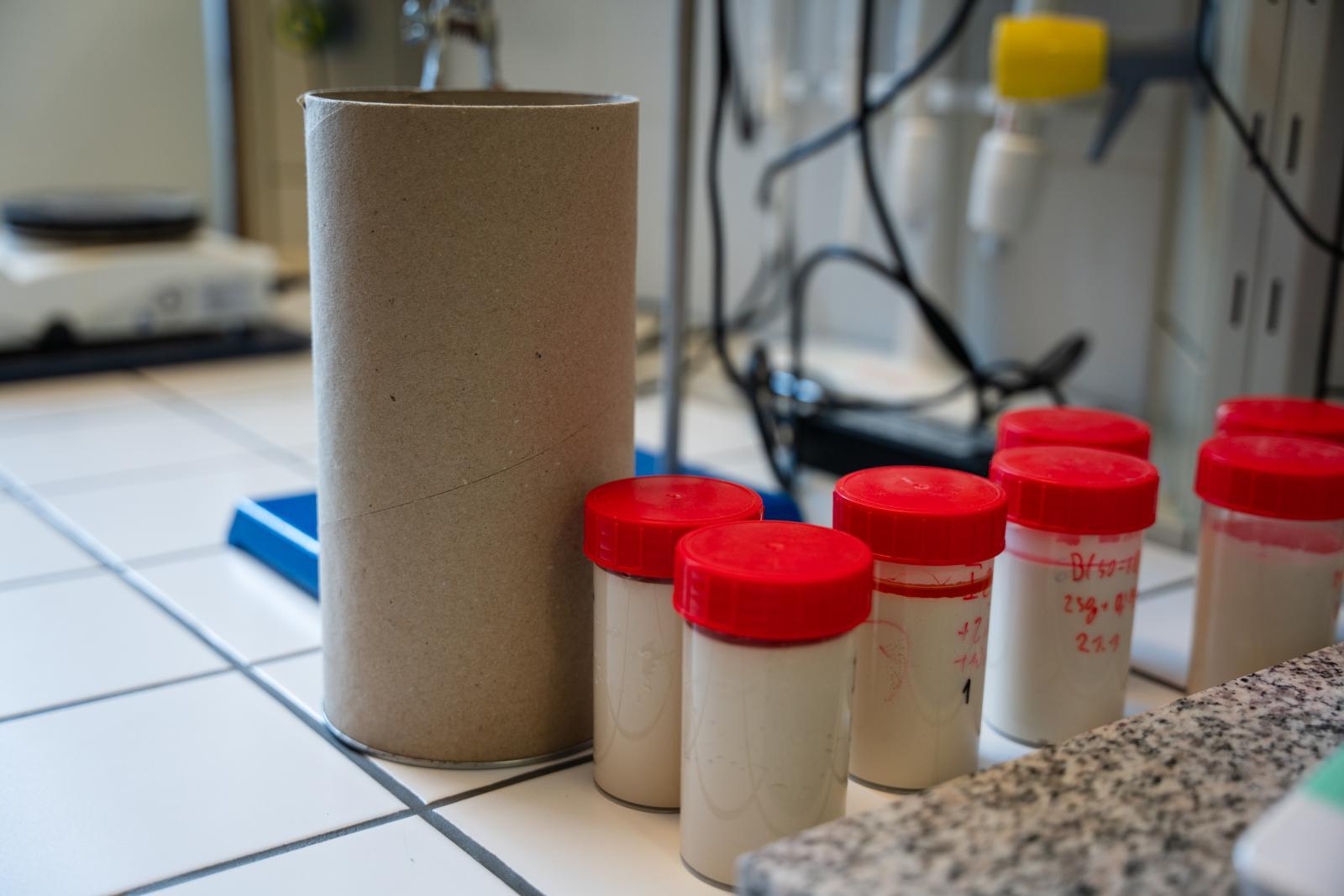

One of the biggest challenges in developing next-generation adhesives is achieving the required elasticity. This property is crucial, especially in manufacturing thin-walled paper tubes, and it is verified directly in customer operations — it can’t be fully simulated in lab conditions. “It's important to distinguish between lab scale and semi-industrial production. You can’t just multiply something by x,” explains researcher Jan Hajzler. Tomáš Solný adds: “The behavior of the mixture in the lab and at a larger scale — say 150 or 1,500 kilograms — is completely different and can surprise you.”

Dextrin is an environmentally benign material — it's easily biodegradable and attractive to bacteria, which poses an additional technological challenge: figuring out how to preserve a natural-based liquid product so that bacteria do not degrade it.

Per Aspera ad Astra: A Sticky Road to the Stars

The road to deploying these adhesives isn’t without obstacles. Overcoming them is one of the project’s key goals. The aim is to make using the new adhesives as seamless as possible for customers. “Dextrin is a great friend to humans — it sticks everywhere, even in your hair,” jokes Tomáš Solný. “It's a sticky matter, and that's how it all begins. The technology can clog up — and it does. When producing homogenized dry mixes, the material can form so-called bridges that prevent free flow. And if you're adding additives that need to be evenly dispersed by the ton, they almost certainly won’t disperse evenly. There are many complications.”

But developing adhesives also brings plenty of joy from progress and unexpected results. “It’s a colorful mix of necessary tasks to complete, and there’s always something to fine-tune,” says Tomáš Solný. The greatest reward, he says, is when the adhesive passes customer tests and they watch its performance in amazement. “They shake their heads in disbelief, saying it’s never worked this well before, and sometimes they’re genuinely thrilled. That’s the feeling of a job well done,” he adds.

The team isn’t afraid of the pressure that comes with high customer expectations and the project’s large ecological and industrial potential. “We enjoy big challenges and aren’t afraid to take them on. What seems impossible one year, often turns out to be possible during the project — almost like snapping your fingers,” says researcher Michal Marko. Tomáš Solný adds: “We probably wouldn’t have said this after the first three months. But results came thanks to the joint effort of everyone involved. I’d sum it up with the Latin phrase *Per aspera ad astra* — through hardship to the stars.”

Out of all the moments accompanying development, the team most remembers the huge leap in adhesive performance. “When we first started putting together basic material formulations, we couldn't get the bonded paper to hold together in under a minute for weeks. And now, we’re discussing whether the adhesive sticks in 5, 10, or 15 seconds,” says Tomáš Solný, adding that they once had an adhesive that only started working after two hours. Today, they have a second-adhesive at hand.

Even Partial Replacement Has a Big Impact

The development of eco-friendly adhesives is now very close to practical application. Numerous production trials have taken place in the Czech Republic and abroad to standardize the product for manufacturing and monitor the quality of final products. Researchers focus on product stability and selecting suitable binder substitutes tailored to specific applications.

Dextrin-based adhesives are especially suitable for the paper and packaging industries, which emphasize the natural character of their products — such as packaging for cereals, premium salt, alcohol, or fire starters. Due to falling oil prices and the war in Ukraine, significantly cheaper raw materials for PVAc adhesives are flooding the market from China, complicating the commercialization of new results.

The idea that ecological adhesives will completely replace synthetic ones is unrealistic — at least in our lifetime. There are countless adhesive formulations in the world, often with very specific properties that natural alternatives can’t fully replicate. Therefore, the research goal isn’t complete replacement, but identifying areas where synthetic adhesives are not essential. “Once we achieved at least partial elasticity with the dextrin adhesive, it started working even in thin-walled tubes — which used to be a problem with dextrin. End users were quite surprised that it could even replace Herkules, the classic white glue,” says Tomáš Solný.

This opens up many applications where petroleum-based adhesives are no longer necessary. “Industrial use isn’t limited — TOPCORE service was even contacted by a luxury shoemaker in Prague who made shoes for Karel Gott or the CEO of Mercedes-Benz in Germany,” he adds. Thanks to this connection and partial use of previously acquired know-how, TOPCORE developed the *Zlatomaz* line of adhesives, now sold worldwide.

Even partial replacement of traditional raw materials can have a positive environmental impact. However, ecological solutions are not always truly more advantageous. “Take paper straws — they can contain up to 0.25 grams of PVAc adhesive per piece and weigh about 1.4 grams, while a standard polypropylene straw weighs only 0.19 grams. When you consider the resources needed to produce the paper and adhesive, their total environmental footprint might be higher than that of the plastic version,” warns Tomáš Solný.

Towards a More Sustainable Future

In the future, the team plans to focus on other eco-friendly materials. A current project proposal focuses on using dextrin-based adhesive systems with additives in particle boards, again in collaboration with TOPCORE service. These systems could partially replace urea-formaldehyde or isocyanate resins, which are still commonly used despite their environmental burden. Tests conducted by a leading particle board manufacturer show that this goal is not unrealistic — though it requires thorough research.

For young people interested in research in this field, the scientists offer some advice. “The field of adhesives and binders for industrial applications is vast. If you choose a research topic carefully, you’ll always find a niche with success potential. It’s important to stay open to new ideas and keep seeking inspiration,” they say.

Equally important, they say, is understanding the industrial environment. PhD students have the opportunity to work with many industrial partners and look for ways to improve efficiency together. “Our alma mater gives students a look behind the scenes of industry — how things are done, how things are ‘cooked.’ I wish them to stay curious. Whether it's chemistry or something else that excites them, they should pursue it with passion, not obligation,” says Tomáš Solný. Jan Hajzler adds: “And don’t let the first failure discourage you. Even a wrong path is still a path and part of the journey.” Michal Marko concludes: “Sometimes making a mistake is the best thing that can happen to you. A mistake can teach you the most.”

-jo-

| Published | |

|---|---|

| Link | https://www.fch.vut.cz/en//f96620/d291558 |