Next-generation ballistic protection: MobiSHIELD from FCH BUT withstands armor-piercing bullets and is easy to install

How can we effectively protect critical infrastructure facilities, such as power plants or government offices, from shooting attacks? Researchers from the Faculty of Chemistry at Brno University of Technology (FCH BUT), in collaboration with other partners, are seeking answers to this question. Long-term development and testing first led to the creation of ballistic protection panels (BPP) made from highly durable cement composite. These were first showcased to the professional public two years ago at the IDET trade fair. Now, the panels are evolving further – into modular ballistic walls under the new name MobiSHIELD.

Ballistic protection panels were developed as part of a TAČR project thanks to the collaboration between FCH BUT and companies Bogges and Excalibur Army, the Research Institute of Building Materials, the Military Research Institute, and the Czech Academy of Sciences. The product meets strict NATO A3 and A4 standards and can withstand armor-piercing rounds up to 12.7 mm caliber, such as those used in machine guns mounted on armored vehicles.

“I can’t imagine ordinary concrete having comparable resistance to BPP while also being movable without machinery, using only human strength. We’re talking about a 5 cm panel replacing more than 15 cm of standard concrete,” explained in 2023 František Šoukal from the Institute of Material Science at FCH BUT, highlighting the main advantages of the solution.

“We established cooperation with FCH BUT representatives at IDET 2023. We then approached them with a request for material development of various connector variants for our construction system, and at the same time, the idea emerged to use it for mounting the ballistic panels developed at the faculty. We subsequently modified the structure for easy panel integration,” explained Vít Plesník from ATHEX Technology s.r.o., describing the beginning of the collaboration.

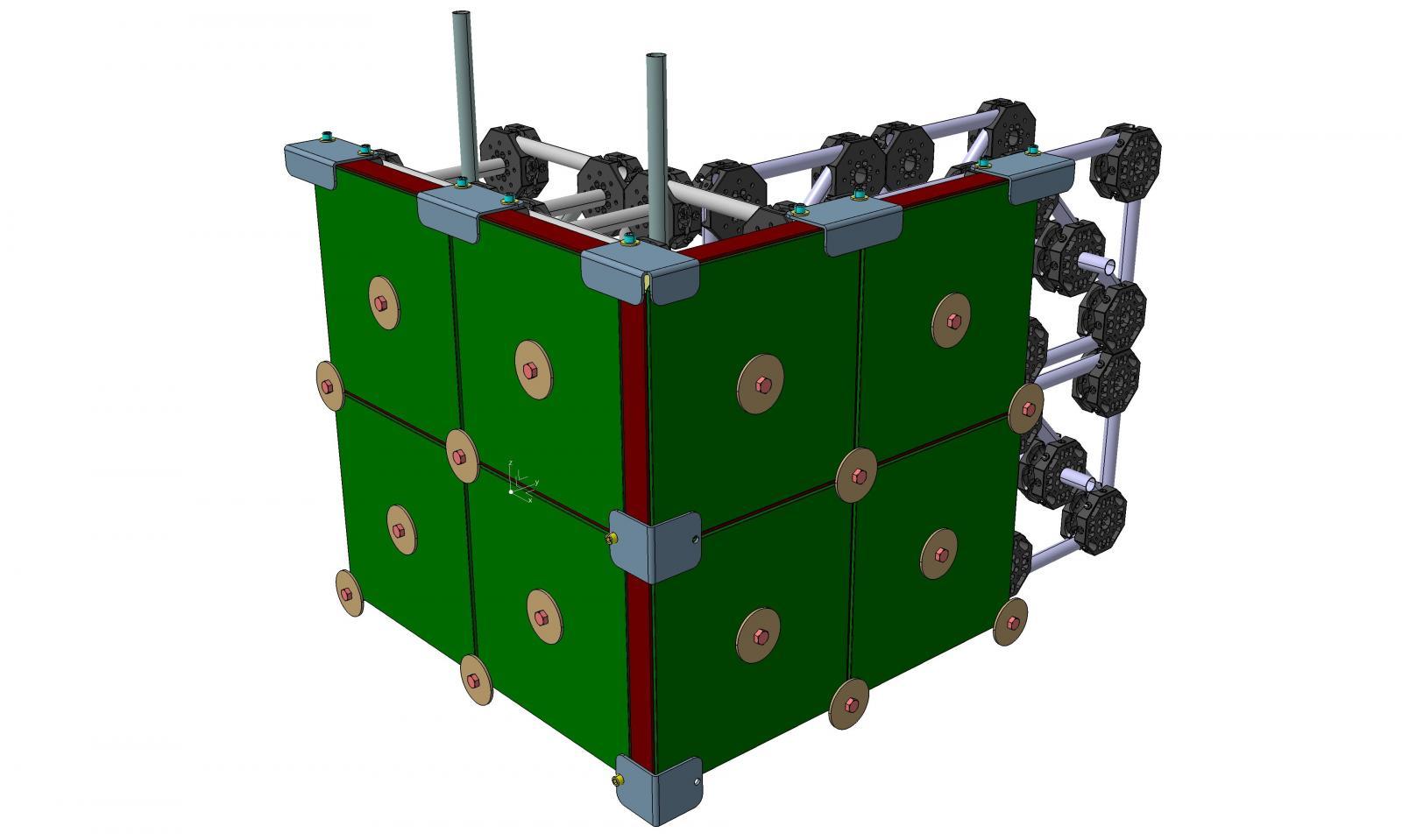

The result is a new system variant, which will be presented at IDET 2025 under the name MobiSHIELD. The panels are mounted into the structure using anchors at the centers and corners, with only minimal gaps between them. “For this year’s BUT exhibition at IDET, we prepared a corner wall fitted with eighteen panels, offering the same advantages as standalone BPPs – high resistance, versatility, easy handling, low production costs, and availability of raw materials,” added František Šoukal.

The availability of input materials and the reliability of the final composite were the reasons for slight adjustments to the composition. “We replaced the original aggregate with a finer, more readily available one. We moved from a cement composite with a maximum particle size of 2 mm to a variant with particles up to 600 µm. This is known as Reactive Powder Concrete (RPC). The result is a more homogeneous and reliable material – as confirmed by ballistic tests, which showed more consistent values than the original mix,” Šoukal offered insight into the development process.

The change in filler also affected the panel dimensions – they now measure 450 × 450 × 75 mm, which is 20 mm thicker than the previous version. However, due to the lower bulk density of the new filler, the surface weight of individual BPP units remained virtually the same. The panel weighs 34 kg, thus retaining one of its key advantages: easy handling without the need for machinery.

The goal is product commercialization. “For exhibition purposes, we can produce the panels in the lab, but with greater demand, this is not sustainable in the long term. That’s why we approached a small concrete company and offered cooperation – in the form of a spin-off or licensing the technology for commercial use. The near future will show which direction the project will take,” concluded František Šoukal.

Source: zVUT.cz

| Published | |

|---|---|

| Link | https://www.fch.vut.cz/en//f96620/d291195 |