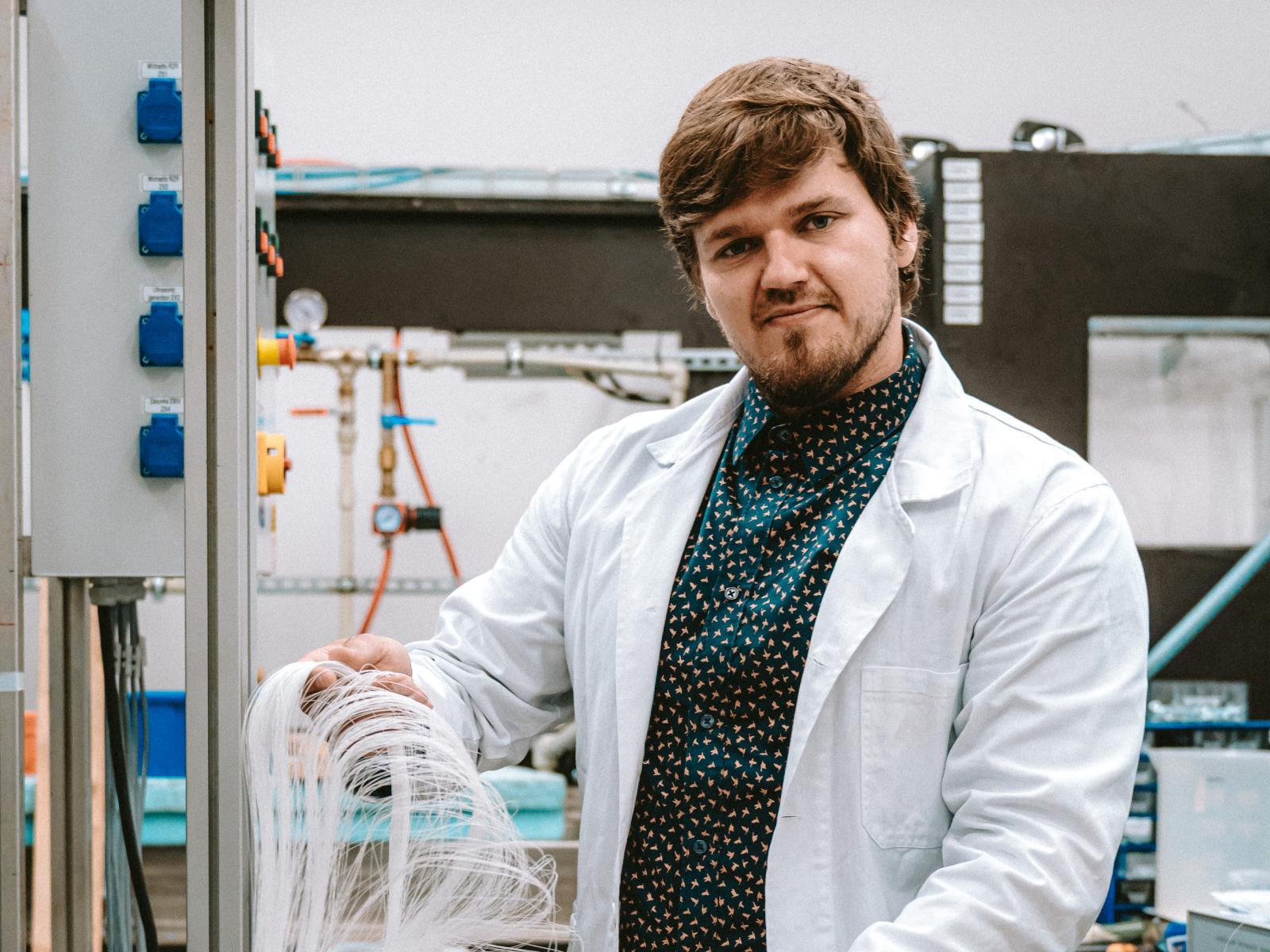

PhD student Jiří Lindovský: I enjoy tackling the challenges of transferring experiments from the lab to practice

How can laboratory experiments be transformed into technologies that work in real operations? And what is it like to present your research to thousands of experts at an international conference? PhD student Jiří Lindovský from the Institute of Chemistry and Environmental Protection Technology at FCH BUT is working on ammonia separation from biogas plant fertilizers and applying his findings directly in practice.

I got to my PhD mainly thanks to the great team I work with, who supported me. It also helped that my master’s thesis project continued after my studies ended, so I was able to smoothly carry on.

In this project, we focus on removing ammonia from digestate from biogas plants and from wastewater in general. We pay particular attention to fertilizers because they contain a high concentration of ammonia. This is the main benefit of our current research – we are trying to reduce ammonia content and minimize its negative impact on the environment.

My supervisor, Associate Professor Komendová, is an expert in chemical analysis, which is crucial for our processes. She gives me the guidance I need, because sometimes I feel lost. Every time I come for a consultation, she gives me new energy.

What led you to the field you are researching today?

Since childhood, I’ve been more inclined towards manual work. I enjoy being able to work with my hands. During my studies, I was still looking for my path – I started with medical applications, thinking my future was in pharmaceuticals, but eventually realized it wasn’t for me. In my third year, I had a class in chemical engineering with Dr. Bulejek. He showed us examples of projects they had worked on, and I found that fascinating because I could see a direct connection to practice, which no other subject had offered me at the time.

I arranged to visit the mechanical engineering department, and that’s how I joined the team of Professor Svěrák and Dr. Kalivoda. During my PhD, I closely collaborate with the mechanical engineering faculty and the company MVB Opava, where we work on the design and construction of equipment. At the Faculty of Chemistry, we then focus on the chemical side of the process.

Why is it important to address ammonia separation from wastewater?

A high concentration of ammonia from fertilizers can seep into groundwater. The biggest issue is for aquatic organisms – fish, invertebrates – because it disrupts their breathing through gills. For humans, ammonia isn’t specifically regulated, but the WHO recommends limits for drinking and utility water. In larger amounts, ammonia is toxic, but no strict legal limit has been set.

How do the membrane processes you use in your research work?

We use hollow fiber membranes arranged in bundles of 1,380 fibers. Their pores are about the diameter of a human hair, so they are invisible to the naked eye, but they separate gas from liquid. In fertilizer, ammonia exists both dissolved and gaseous. We try to drive the dissolved ammonia into the gas phase – partial pressure forces it out of the liquid, through the membrane pores, and then it is absorbed into another liquid. It is a mass transfer process at the liquid–gas interface.

What challenges do you face when developing membrane processes?

The membrane processes themselves are developed, but the biggest challenge is to bring them into operation. We cooperate with the company agriKomp Bohemia, which operates biogas plants, and the aforementioned MVB Opava, with whom I implement the design of the equipment based on my proposal.

How does your approach differ from other wastewater treatment methods?

In the literature, this method is not described as being used in practice. Most often, experiments are tested in laboratories, where they work well, but problems appear when scaled up to reality. That’s what we deal with – and we are among the few who do. This issue is especially relevant in Europe, since biogas plants are mainly widespread here.

What fascinates you most about this topic?

The combination of theory and practice. I can theoretically calculate efficiency, design a process, carry out experiments, and then see whether theory meets reality. Sometimes it matches exactly, sometimes only approximately (laughs). In the lab, we experiment with small volumes under controlled conditions, but on-site we scale up the process and apply it in full operation. That’s where factors appear that you can easily control in the lab, but not in real environments – and solving those problems is what fascinates me.

The whole team is important. We work together on the research from start to finish; it’s not like I only deal with one specific thing. Sometimes even my family members, who aren’t chemists, give me useful advice thanks to their outside perspective. I also spend a lot of time with my cousin, who is a watchmaker. When I’m home in Ostrava, we sit over coffee, and after the third cup, the discussions start flowing – we’re like caffeinated squirrels (laughs). My cousin has a great feel for manual work and focuses on surface treatments, especially electroplating. At the faculty, we faced a problem with porous fibers functioning as membranes, but also with fibers that should function as heat exchangers. The problem was that water vapor penetrated through the polymer structure, which was unacceptable. My cousin suggested: “What if you tried modifying the fiber surface, maybe electroplating it? They would retain conductive properties, but the pores would be covered with a metallic layer.”

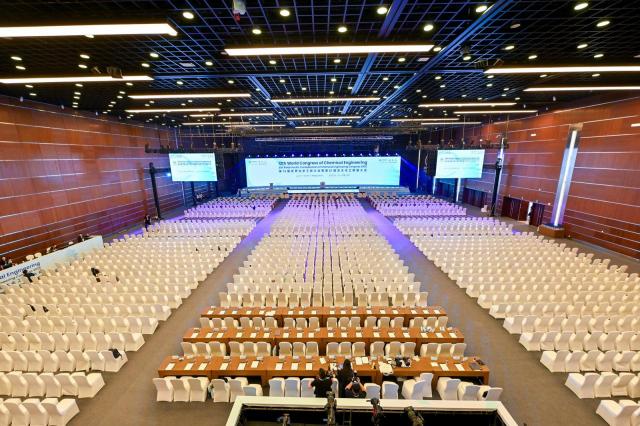

You recently attended an international conference – what was it and what were the main topics?

It was the 12th World Congress of Chemical Engineering, the largest global chemical engineering event. It was held in Beijing and had an estimated 10,000 participants. It covered all sorts of topics, some quite unexpected. There were discussions on chemistry education at high schools and universities, and of course, various chemical disciplines like separation processes or biotechnology. The conference focused mainly on the use of chemistry in medicine, but also addressed global warming, environmental protection, carbon neutrality, and similar issues. These are topics that interest me, so I tried to absorb as much as possible.

Did you present your research?

Yes, I gave a presentation about what we are doing at the faculty. The conference was divided into sections, and I was in the one dealing with water treatment and environmentally applicable processes, particularly membrane ones.

There were a lot of questions after my talk, and they took it seriously. They mainly asked about membranes, because their focus is more on the development of materials and the membranes themselves. We focus on the application, so I explained that for us it’s not crucial what the membrane is made of – polyethylene, polypropylene, or Teflon – the differences in separation efficiency are minimal.

What did participating in the conference give you – professionally and personally?

I had the opportunity to talk with people who are far more experienced than me. I always get advice from them that I can use in my professional life. In addition, there were plenary lectures with very interesting speakers from well-known Asian companies like Mitsubishi, Huawei, or Sinopec, which also have chemical divisions.

One example that struck me was a study showing that there is currently half a car per person in the world, and by 2050 it will be one car per person. Another presentation combined data processing and artificial intelligence – a student from Australia developed a camera system capable of distinguishing seashells on the ocean floor by size and shape and separating them from stones and other objects. That was fascinating and showed how technologies from other fields can also be applied in natural sciences.

I also made contacts and friendships with people from many different countries, with whom we discussed mainly scientific topics. It was interesting to learn how things are done there. As for my topic, almost no one in Asia deals with it – ammonia emissions are not a problem for them; they focus on modern technologies.

Where could the results of your research be applied?

The results will be applied primarily in agriculture, in fertilization using biogas plant fertilizers. At a biogas plant, they have an organic input or other substrate, which produces gas through methanogenesis. This gas powers cogeneration units to produce electricity. The organic residue, from which methane has been extracted and which has limited usability, goes to a storage tank. Tractors pump it out from there and spread it on fields.

The problem is that this fertilizer has a high ammonia content – up to 7 grams per liter. That is a level that often threatens groundwater quality, where ammonia must not be present at all. At high concentrations, nitrifying bacteria can overgrow, leading to soil eutrophication. The research is also applicable to other environmental technologies, such as CO₂ separation.

What are you currently working on and what are your future plans?

Right now, I am working on non-membrane separation, specifically ammonia desorption using elevated temperature. We are trying to convert gaseous ammonia into a useful product. The gaseous ammonia is bubbled through a liquid, where it reacts to form a slightly soluble ammonium salt called struvite. It is a slow-release fertilizer. We take ammonia and convert it into a substance with a defined ammonia content, where the dosage can be controlled.

As for future plans, I am heading for an internship in Japan, where I will work with fibers. But I will continue to support my colleagues in Brno remotely as much as I can. After completing my PhD, I want to gain experience outside academia. When I work directly in real operation, I see what kind of business-side experience I lack.

What would you say to students considering a career in sustainable chemistry?

It’s not for everyone, but I’d like to say this – throughout my studies, I often encountered the view that many people don’t accept that even bad results are still results. I once attended a conference where a speaker from a Czech company producing membranes gave a presentation. He set out goals at the beginning and, at the end, went back to them: first goal – failed, second goal – failed, third goal – failed, fourth goal – failed. And that was the end of his talk (laughs). At first glance, it looked like he achieved nothing, but that’s still a result – he found out that this approach doesn’t work. Knowing that, we can take a different direction that may work. Moreover, we help others in the field by showing them what not to try.

Any final words?

In conclusion, I would like to invite all colleagues to the 13th World Congress of Chemical Engineering, which will take place in 2029 in Prague. The conference chair will be Professor Juraj Kosek from the University of Chemistry and Technology in Prague, and besides chemistry and chemical engineering, biotechnology will be a major theme. Professor Kosek would be happy if we contributed to the organization and, of course, took part as participants. This conference is also a great opportunity to promote both the Brno faculty and the whole team engaged in this important field.

Thank you for the interview, and we wish you much continued success!

-jo-

| Published | |

|---|---|

| Link | https://www.fch.vut.cz/en//f96620/d303536 |